Project Details

| WORK NAME | Treatment Plant For Kayseri Organize Sanayi Bölgesi |

| PLACE OF WORK | : Kayseri |

| CAPACITY | : 40.000 m³/day |

| KOİ | : 2.000 mg/l |

| BOD5 | : 2.250 mg/l |

| EQUIVALENT POPULATION | : 1,000,000 people |

| AKM | : 1000 mg/l |

| pH | : 8 |

| TREATMENT PROCESS | : Physicochemical Treatment & Selector Activated Sludge Plant |

| WORK DONE | Project & Equipment Supply & Turnkey |

| DATE OF WORK FINISHED | : 2016 |

| TREATMENT PLANT EFFLUENT CONCENTRATIONS | |

| TSS (mg/lt) | : 30 |

| COD (mg/lt) | : 100 |

| BOD (mg/lt) | : 30 |

Story of the Project

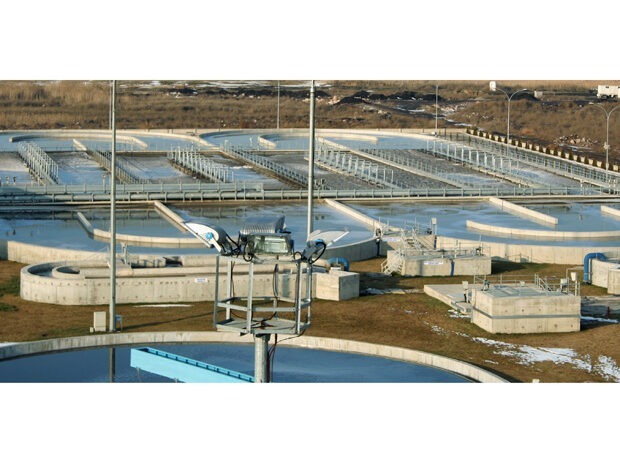

The Kayseri Organize Sanayi Bölgesi (Organized Industrial Zone), stands as one of Turkey's most significant industrial hubs, housing factories from diverse sectors. In 2016, the Kayseri OSB Wastewater Treatment Plant, completed and commissioned by Ekosistem Engineering, offered an environmentally friendly solution by addressing the wastewater treatment needs of all factories within the zone.

A hallmark of this facility is its ability to treat wastewater from various industrial sectors without harming the environment, ensuring safe discharge into nature. Moreover, this project serves as a model not only for the Kayseri OSB but also for other industrial zones across Turkey. Recognized as an award-winning project, this plant has contributed to the sustainable growth of Kayseri's industrial sector without compromising the environment.

Water Ecosystem and Sustainability

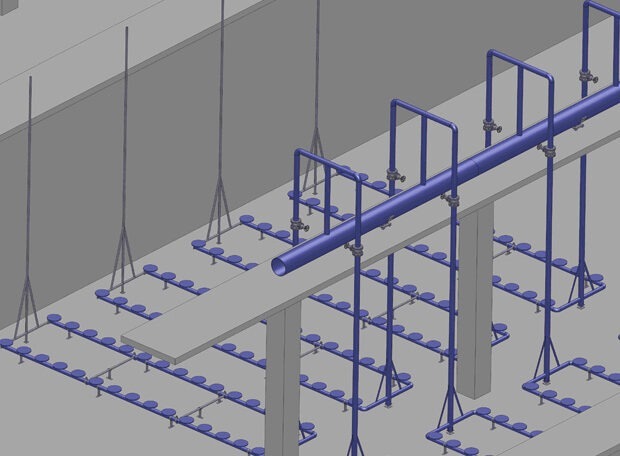

The Kayseri OSB Wastewater Treatment Plant stands out with innovative solutions that minimize its environmental impact. One of the most significant sustainability features is the use of modern treatment technologies focused on energy efficiency. Through physicochemical treatment and activated sludge processes , energy consumption is minimized, reducing the carbon footprint. This not only minimizes environmental impact but also contributes to lower operating costs.

With a daily capacity of 60,000 m³, the Kayseri OSB Wastewater Treatment Plant is designed to meet the wastewater treatment needs of a population equivalent to approximately 1 million people. The plant significantly reduces the pollution load in wastewater, lowering the Chemical Oxygen Demand (COD) value from 2,000 mg/l to 100 mg/l and the Biological Oxygen Demand (BOD5) value from 2,250 mg/l to 30 mg/l. Additionally, the suspended solids concentration (TSS), initially at 1,000 mg/l, is reduced to 30 mg/l at the plant outlet. The plant maintains a pH level of 8, ensuring effective treatment.

Furthermore, the plant's advanced filtration and separation systems used in the wastewater and mud treatment process contribute to the conservation of natural resources. By enabling the reuse of treated water, the plant reduces water waste and takes a significant step towards sustainable water management. This allows industries to utilize natural resources more efficiently and reduce their environmental footprint.

This modern facility ensures the safe return of wastewater to nature by employing advanced technologies in its treatment processes. Ekosistem Engineeringprovided a comprehensive solution for this project, including equipment supply, installation, project management, and commissioning. Following the completion of works in 2009, the plant began operating efficiently.

The Kayseri IOZ Project Sets an Example for Turkey and Differentiates Itself from Competitors

The Kayseri OSB Wastewater Treatment Plant stands out from its competitors not only in terms of its technical aspects but also in its commitment to environmentally friendly solutions. One of the most distinguishing features of the plant is its ability to effectively treat wastewater from a wide variety of industrial sectors within a single system. Such versatile treatment capacity on such a large scale is rare. With a total capacity of 60,000 m³/day, the plant is one of the largest projects in the sector, successfully treating wastewater from both large and small industrial establishments.

From a social perspective, the Kayseri OSB Wastewater Treatment Plant has contributed to the growth of the region's industry while increasing environmental awareness. This plant has not only benefited the environment but has also helped create a cleaner and more livable environment for the local community. By ensuring access to clean water sources for people living in industrial zones, it has had a positive impact on local communities.

Ekosistem Engineering's turnkey solution is another key factor that sets this project apart. This integrated service, encompassing equipment supply, installation, project management, and commissioning, provided a significant advantage for investors and ensured the seamless commissioning of the plant.

If you want to increase the energy efficiency of your facility and reduce your carbon footprint, feel free to contact us!